Using a CETAC autosampler with 96-well microplates

|

This page describes equations to convert a sequential sample number into an exact xy position on a series of 96-well microplates. We had to do this, because we wanted to use a standard CETAC (now Teledyne CEATC) autosampler with an instrument software, that sends a rack type and a sample number to the autosampler, but its software does not know microplates as a racktype. We

have done the equations for 96-well type microplates,

but with some mathematical skills you should be able

adapt them to microplates with 192 or 384 positions.

Note that the sample numbers for the equations start

with POSition 0 while the microplate positions are

numbered 1 to 96. We

use a CETAC

ASX 520 autosampler (AS) with both a Varian

Vista Pro and an Agilent

720 ICP-OES that are both controlled by XP

versions of ICP Expert. Both the Agilent / Varian

Software and the CETAC software only know the CETAC rack

types and cannot directly deal with microplates. The

CETAC ASX software is yet capable of accepting absolute

positions in 0.1mm resolution (x and y) and 1mm

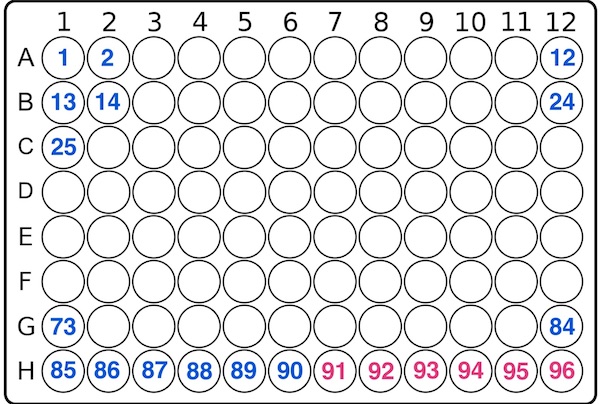

resolution (z). The rack closest to an 8x12 microplate is the rack type 90 (90 sample positions) so when you set rack type 90 in the ICP software you can use it to take samples from 90 of the 96(8x12) positions of the microplate. The graphic representation of the sample positions on the rack in the ICP software will thus be meaningless. The ICP software sample positions are mapped to the microplate like this:

96-well

microplate layout. Blue: sample numbers from

ICP-software. Red: these samples are not accessable when

using a rack type 90. So position 91 will be on the

second rack in the ICP software and on the second

microplate. Technically it would be no problem accessing

the last six positions, we just thought its more

intuitive when samples on microplate 1 are only rack1

and position 91 (=position 1 on rack 2) is mapped to the

first position on the second microplate. In

the AS software command syntax, all position numbers are

one less than the position numbers our ICP software. So

in the AS commands the first position is position 0

while in the software and on the racks it is called

positon 1 Example: If

you want to use the Cetac ASX 520 with microplates, you

have to convert the sample positions from a rack that it

knows (we use RACK=90 - a 6x15 Rack) into absolute

positions. Microplate

dimensions Microplates

have a footprint of 85.5x127.8 mm (approx. 3.4" x 5.0").

In a 96-position (8x12) microplate the hole centers have

a distance of 9mm (approx. 0.35") in both x and y

directions. The centers of the outer rows have a

distance of 11.2mm (approx. 7/16") from the outer edges

along the long sides. On the short sides, the centers of

the outermost row are 14.3mm (approx. 9/16") away from

the outer edges. x=

x_0+(INT(((POS+6*INT(POS/90)))/12))*90+d_rack*INT(POS/90)

If

the wellplates are positioned with the long side

parallel to the AS case the equations change to: Position 1 is then in row close to the AS case on the left and positions count to the right and rows count towards the user.

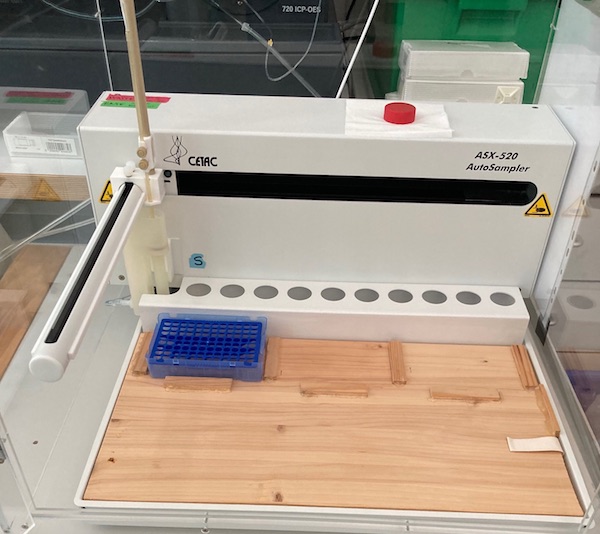

We

have constructed a quick and dirty adapter that fits

smoothly into the plastic guide for the standard racks

which can hold three wellplates parallel to the AS case.

In the picture, there is a 8x12 pipette tip rack in the

first microplate position. the

parameters for this setup are for example: These

numbers can be changed in our little software, that

simply contains the equations above as user definable

with the only variable being the position POS (= 0

to 89) that is being sent from the ICP-Software. x

position:

140+(INT(((x1+6*INT(x1/90)))/8))*90+340*INT(x1/90) where both x1 and y1 are equivalent to POS. If

you need to adjust positioning, carefully change the x0

and/or y0 parameters in the equation. We just had to

readjust our needle positioning by 2mm to the left by

reducing to x0 = 120.

d_rack may be calculated from : Remark - totally irrelevant for using microplates with Varian/Agilent software, we just happened to find out: In

the Varian/Agilent ICP software you are allowed to mix

racks. This only works, because the software pretends to

the AS there is only one rack type and renumbers

accordingly: If this page helped you, you can help us by clicking on our latest research paper in nature geoscience It is on CO2 release from continental shelves and you can read it for free here The paper has

a wonderful graph

that shows the relation between CO2 and

sea-level during the last 800,000 years. |